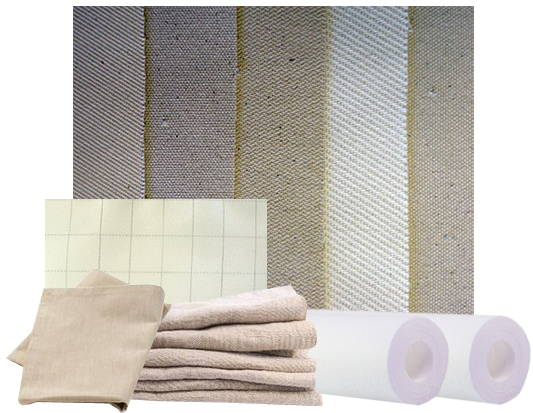

Filter Cloth

The most important considerations in choosing a fiber for filtration is the type of filtration and the environment in which filtration or dust collection will take place. The following should be taken into account:

- Type of Filtration: (a) Air or (b) Liquid

- Heat Resistance

- Chemical Resistance

- Physical Properties

Air Filtration - the most common objectives are purification (either incoming or outgoing) and recovery of a product. In some applications the two can be combined for beneficial results. Many installations made for purposes of air pollution control have resulted in the recovery of a usable product. For example, a smelting plant will recover valuable dust; a power plant collects fly ash, which is usable as an aggregate in concrete, etc.

Liquid Filtration - the three main objectives are refining a product, recovering a product and clarifying the filtrate. Filter cloth qualities for liquid filtration would include the ability to prevent passage of a solid material, allow an even flow of liquid, resist plugging, and ease of filter cake removal.

Our cloth is expertly and accurately cut and punched to your specifications at our facility. A latex border can be added to some fabrics for greater sealing performance during your process.

Our experienced technicians can recommend the right cloth for your process.

Start a Project

At Kavon Filter Products we are able to get the job done right the first time. We provide a level of quality that surpasses our customers’ expectations while enhancing their position in the marketplace.

request informationproducts and capabilities

We manufacture quality replacement fluid bed dryer bags, sleeves, skirts, chutes and sleeves for cartridge filter units, as well as centrifuge liners and bags. Kavon Filter Products Co. is an authorized distributor for Ahlstrom-Munksjö filter paper and we stock many commonly used filter papers.

Browse our catalog

Print This Page

Print This Page